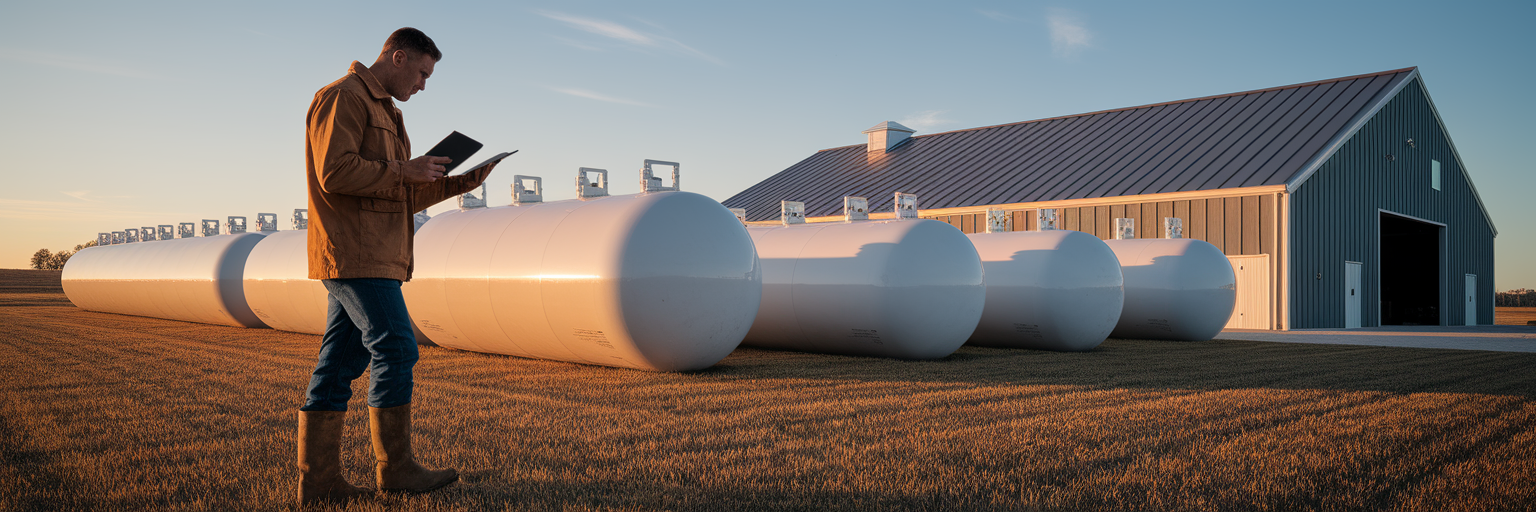

The Unique Demands of Propane Management on Large Properties

When a single home runs out of propane, it is an inconvenience. When a resort’s heating fails in winter or a farm’s crop dryers shut down mid-harvest, it becomes a critical operational failure with serious financial consequences. The stakes are simply different. Effective propane management for large properties is not just a scaled up version of residential tracking; it is a distinct logistical challenge that demands a strategic approach.

Properties with multiple tanks spread across a large area face three primary risks. The first is operational disruption. A surprise run-out can halt everything from commercial kitchen operations to heating for guest cabins, directly impacting revenue and reputation. The second risk involves unpredictable costs. Without a clear view of consumption, budgeting for propane becomes a guessing game, leading to financial instability.

Finally, there is the heavy administrative burden. Coordinating manual tank checks, logging data, and scheduling deliveries for numerous tanks is a time consuming and inefficient process. This reactive cycle of checking and refilling leaves no room for proactive planning. The challenge is to move away from this constant fire drill and toward a system that provides control, predictability, and peace of mind.

Foundational Tracking Through Systematic Manual Checks

Before you can manage your propane supply, you need a baseline understanding of your usage. The most fundamental method is a systematic manual check. This process starts with learning how to track propane usage directly from the tank. Most propane tank gauges display the fuel level as a percentage. It is important to know that a “full” tank typically reads around 80% to leave room for the gas to expand with temperature changes. A good rule of thumb is to schedule a refill when the gauge drops to the 20-30% mark.

To make this process effective across multiple tanks, consistency is essential. Create a dedicated logbook, either a physical notebook or a simple spreadsheet, with columns for key information:

- Tank ID or Location: A clear identifier for each tank (e.g., “Guest Cabin 4” or “North Barn”).

- Date: The date of the check.

- Gauge Percentage: The reading from the tank gauge.

- Notes: Any observations, such as unusually fast consumption or signs of a leak.

While performing these checks, always adhere to proper safety protocols around the equipment to ensure the well being of your staff. This manual method provides a starting point for understanding consumption patterns. However, its limitations become apparent at scale. It is labour intensive, prone to human error during reading or data entry, and provides no real time information. A sudden cold snap or an unexpected increase in operations can drain a tank far faster than your weekly check schedule can catch, leaving you vulnerable. Manual checks are a necessary first step, but their inefficiencies often justify exploring more advanced methods.

Estimating Consumption by Analyzing Appliance Load

Moving beyond physical checks, you can build a predictive model of your propane use by analyzing the equipment connected to each tank. This approach helps you calculate propane consumption for property assets based on their technical specifications rather than just gauge readings. The core of this method is a straightforward formula: an appliance’s BTU rating divided by 91,500 (the number of BTUs in one gallon of propane) gives you the gallons used per hour of operation.

For properties in the hospitality sector, understanding the consumption patterns of kitchens and laundry facilities is key to effective management. High-draw equipment common on large properties includes commercial kitchen ranges, industrial laundry dryers, and large heaters for pools or agricultural buildings. By calculating the hourly consumption of these appliances, you can create a detailed forecast. For example, knowing a crop dryer uses nearly 11 gallons per hour helps you plan refills accurately during harvest season.

| Appliance Type | Average BTU/Hour Rating | Estimated Propane Usage (Gallons/Hour) |

|---|---|---|

| Commercial Kitchen Range (6 burners) | 180,000 BTU | ~1.97 gal/hr |

| Commercial Clothes Dryer | 120,000 BTU | ~1.31 gal/hr |

| Large Pool/Spa Heater | 400,000 BTU | ~4.37 gal/hr |

| Patio Heater | 40,000 BTU | ~0.44 gal/hr |

| Agricultural Crop Dryer | 1,000,000 BTU | ~10.93 gal/hr |

Note: These figures are estimates. Actual consumption can vary based on appliance efficiency, usage intensity, and environmental conditions. BTU ratings are sourced from typical manufacturer specifications for commercial-grade equipment.

This model becomes even more powerful when you factor in variables like seasonality, business hours, and occupancy rates. While it does not provide real time levels, this analytical approach is an excellent tool for budgeting and long term planning.

Implementing Remote Monitoring for Centralized Control

For properties managing a complex network of tanks, technology offers the most robust solution. A remote propane tank monitoring system automates data collection and centralizes control, eliminating the inefficiencies of manual methods. These systems use sensors installed on each tank to transmit real time fuel levels to a single dashboard, accessible via a computer or mobile app. This gives a manager a “single pane of glass” view, allowing them to see the status of every tank on the property without leaving the office.

The practical benefits of a multi tank propane monitoring system extend far beyond simple level readings. Advanced features transform raw data into actionable intelligence for commercial propane consumption tracking.

- Historical Data Analysis: With months or even years of data, you can identify long term consumption trends, pinpoint seasonal peaks with precision, and spot anomalies that might indicate an equipment issue.

- Customizable Low Level Alerts: You can set different notification thresholds for each tank. A generator for a critical system might trigger an alert at 40%, while a tank for patio heaters could be set to 20%.

- Consumption Reports: Automated reports provide clear data for budget forecasting, helping you negotiate better terms with suppliers based on predictable usage patterns.

These systems, which typically use reliable cellular or Wi-Fi technology, are particularly effective for large scale commercial operations, from resorts to agricultural enterprises. They replace guesswork with certainty, turning reactive scrambling into proactive management.

Developing a Proactive Propane Replenishment Strategy

Gathering accurate data is only half the battle. The true value comes from using that information to build a proactive replenishment strategy. The goal is to move beyond emergency refills and create a schedule that ensures uninterrupted operations without the cost of storing excessive fuel. With a clear history of your propane consumption, you can collaborate with your supplier to establish a truly customized delivery plan that aligns with your actual needs, not a generic calendar.

This is where turning data into operational intelligence really shines. You can set dynamic alert thresholds based on the importance of the equipment each tank serves. For instance, a tank supplying a backup generator might be flagged for a refill at a 40% level to guarantee readiness, while a tank for a seasonal pool heater can safely wait until it hits 20%. This level of planning is essential for facilities where uptime is non negotiable, such as in warehouse operations.

By implementing this strategic approach, you transform your propane management from a logistical headache into a streamlined process. The benefits are clear: superior budget control, stronger negotiating power with suppliers, a significant reduction in administrative work, and complete operational peace of mind. You are no longer just buying propane; you are managing a critical resource with precision and foresight.

About Jennifer Whitaker

Propane industry expert and content contributor for MyPropane.com.

View all posts by Jennifer Whitaker →Related Articles

Five Propane Tank Mistakes That Risk Your Home's Safety

Oct 29, 2025 • 8 min read

Discover simple, effective ways to maintain your propane system and prevent hazardous situations with our straightforward advice.

Propane Generators: Portable vs Standby Power Solutions

Sep 17, 2025 • 8 min read

Compare propane generators: portable vs standby systems. Learn about power output, fuel efficiency, installation requirements, and cost considerations for home…